D3D-s Scanners – Precision Scanning for

Model Makers

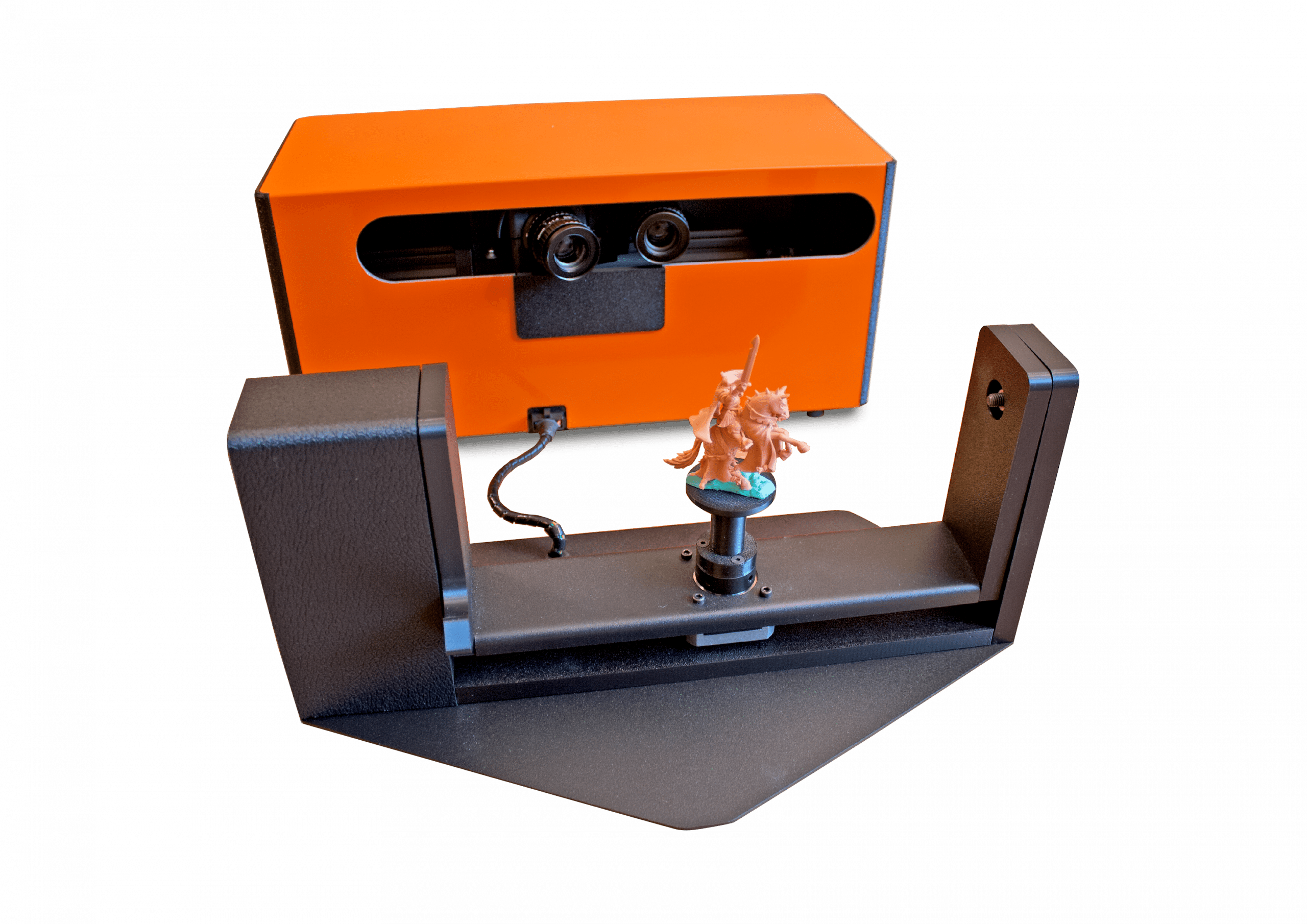

Designed and manufactured in Ukraine, D3D-s scanners give model makers

the fidelity and speed needed to digitise masters, restore vintage pieces, and

reproduce parts with confidence. From tabletop miniatures and kit-bashes

to architectural components and film props, D3D-s delivers clean, high-detail

meshes that drop straight into your build pipeline.

Why model makers choose D3D-s:

• Fine-detail capture: Micron-level surface resolution preserves panel lines, textures, and tiny geometry.

• Fast, reliable workflow: Guided capture and rapid processing keep projects moving on deadline.

• Compact & robust: Desktop footprint with workshop-ready durability.

• Open formats: Export STL/OBJ/PLY for any 3D printer, CNC, or DCC/CAD package.

• Seamless integration: Works with Blender, ZBrush, Rhino, Fusion 360, SolidWorks, KeyShot, Unreal/Unity, and more.

• Repeatable accuracy: Stable calibration for consistent results across sessions and operators.

Benefits:

• Reduce hand-measuring and rework

• Lock in symmetry and fit for multi-part assemblies

• Shorten time from concept to mold/print

• Create searchable libraries of components and masters

• A simple, dependable workflow

• Position the part (turntable or fixed), minimal targets needed.

• Scan with live coverage feedback to ensure every undercut is captured.

• Process (auto align, clean, and mesh) with manual tools when you need them.

• Export watertight files for printing, milling, or further sculpting.

• Best practices for tricky parts

• Apply a light matte spray on glossy/clear areas.

• Use small risers to expose edges and undercuts.

• Scan sub-assemblies, then align digitally for cleaner meshes.